Risk analysis is often overlooked as a tool in project planning. However, predicting potential delays in advance and understanding the impact on a project can go a long way to making a project successful. This article helps anyone on the project team understand the role of risk analysis and how it is done on a schedule.

What is Schedule Risk Analysis?

Schedule Risk Analysis (SRA) is a process to determine the achievability of a schedule and its chance of meeting the project’s defined goals. It is a quantitative analysis and is based on mathematical calculations, enabling the project to monitor potential schedule delays through the life of the project.

How is it done?

Perhaps the most well-known and popular method for SRA is the Monte Carlo Simulation. This technique simulates the project schedule progress before it occurs but in numerous runs, each time with a different set of variables (alternatives). The scheduler chooses the variables, as well as the distribution and parameters of each.

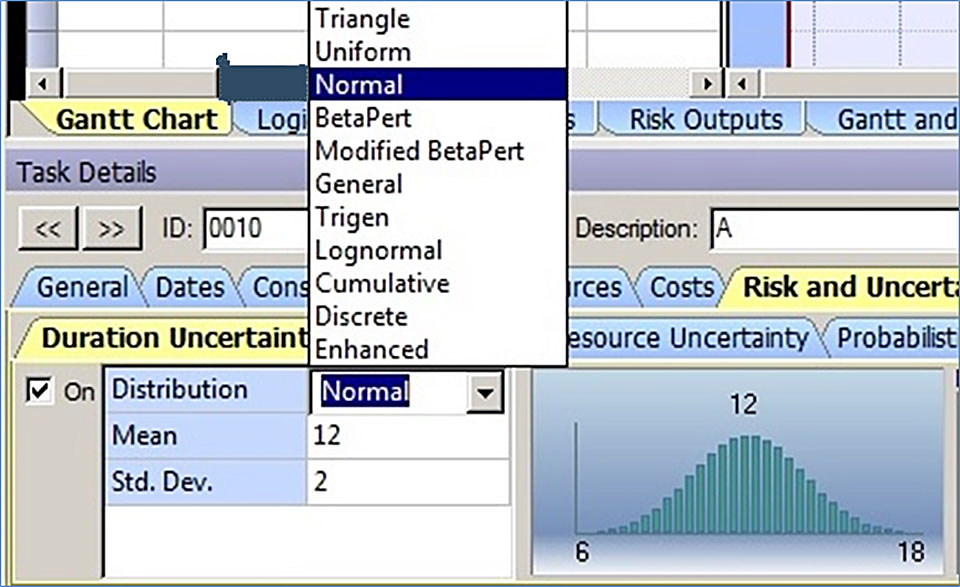

To give an example, assume we have a sea freight activity planned in our project for two years from now. It is generally believed that such freight would take 8 weeks (including paperwork on both sides) but things normally go differently in the real world. Experience has shown that if everything is in place and the parcel doesn’t have to wait for the vessel, the shipment can be done as quickly as 5 weeks. On the other hand, if we have errors in the paperwork and have to wait for a following vessel, the shipment can easily take up to 11 weeks. In this example, instead of simply scheduling our activity with one certain duration of 8 weeks, we use a normal distribution with a mean of 8 and standard deviation of 3 weeks. This allows the simulation to use various values as the duration of this activity – all taken from the defined distribution – for each run.

Similar to the example above, there are many other activities that have an uncertain duration and may constitute a schedule risk. Therefore, the process above is repeated for all such activities that are normally on the critical path of the schedule (or the first few critical paths). When the simulation is running, each iteration uses a set of these variables, each taken from a defined distribution rather than one certain duration.

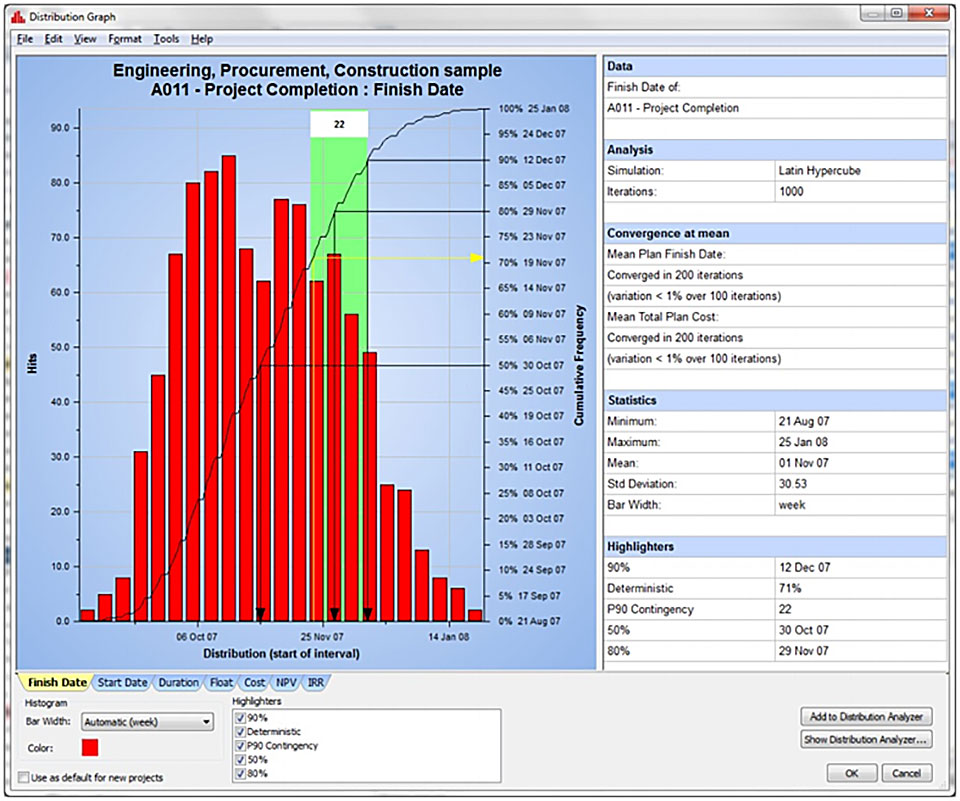

The results of simulation iterations (i.e. completion date of the schedule) are aggregated into a curve that demonstrates the probability of completing the project at any certain date. If an applicable software tool is used, such as Primavera Risk Analysis, several additional analyses and reports are also generated to show the main pitfalls of the schedule related to potential time delays and relevant risks.

How can it help?

Clearly, both external and internal clients can benefit from the results of this work. Once complete, the SRA can become one of the most popular reports with the project team. It helps foresee potential delays in quantitative terms while continuing to monitor them throughout the entire project timeframe. This means there are many opportunities for the SRA to provide value. As an example, frequently produced SRA results can provide valuable input to a 6-sigma analysis of potential project delays.

Why is it sometimes neglected?

Even though SRA is well-known among many organizations, it is still not widely used as a standard part of project controls. Lack of time, resources, knowledge or experience are often barriers to use. Also, the project team’s culture plays a role in how often SRA is used. These obstacles can be overcome by skilled project controls professionals who are willing to help educate the project team on the benefits of producing periodic SRA’s.

Has your project team incorporated quantitative schedule risk analysis? Give it a try and discover important information about your project.

Maziar Rad joined CM Solutions in 2020 as a scheduler for airside and landside projects with the Los Angeles International Airport and the Van Nuys Airport. He has 14 years of experience in scheduling and project planning for infrastructure and oil & gas industries, representing both owners and contractors. Maziar has an MBA from the University of Houston and a masters in production and operations management from the Chalmers University of Technology in Sweden. In addition, he is certified as a Scheduling Professional (PMI-SP) through the Project Management Institute.

Back to news

Back to news